What is media blasting? Media blasting is a surface treatment process that uses various media, such as glass beads, dry ice or other materials, to clean, texturize and finish surfaces. It is widely used in industries like aerospace, semiconductor manufacturing and medical device production, where precision media blasting is essential to maintain quality and performance.

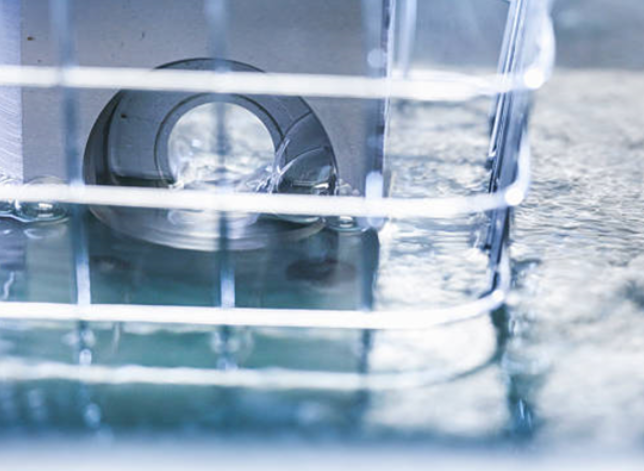

The media blasting process propels media particles at high pressure onto a surface to remove contaminants, oxides and residues. Different types of media are used based on the desired finish and the material being treated. TMPI offers:

Bead blasting, often referred to as “crushed glass,” is silica-free, non-toxic and is optimal for conditions where the contaminant or substance is difficult to remove and may be embedded or entrapped in the surface.

This process removes the targeted surface material which can be difficult to accomplish through non-mechanical processes.

Common Glass Bead Blasting Applications & Uses:

Media blasting works by determining the appropriate media blasting media, such as glass bead blasting vs. dry ice blasting, and pressure settings needed for the component.

Then, the media blasting process begins and effectively removes contaminants while maintaining structural integrity. The part is carefully cleaned and checked it meets the required finish.

No, media blasting is designed to clean and texturize surfaces without significant material removal. It is designed to clean and texture surfaces without altering their dimensions.

The process duration varies based on the component size, media type and contamination level.

For high-precision media blasting services and bead cleaning services, contact TMPI today to discuss your specific requirements.

Our expertise in non-abrasive blasting ensures the highest standards of quality and reliability.

If you’re searching for media blasting and media texturing services, TMPI provides glass bead blasting services for a variety of industries. Get started by contacting us today.

Parts come packaged in standard (ULO) Ultra-Low Outgassing Polyethylene or Nylon material

Cost-effective methods for shield kit cleaning to recover the maximum yield allowed per kit.

Removal of hydrocarbons and other contaminants from sensitive instruments that is measurable and repeatable

Helium is an inert, stable, and non-condensable gas that is often used as a tracer gas to identify leaks in parts and systems.

Specialized cleaning for gaseous oxygen and liquid oxygen components, equipment, piping, and systems.

Copyright © 2024 TMPI. All Rights Reserved.

Terms of Use | Privacy Policy | Compliance | Accessibility Statement